Ever wondered how electric cars get their juice or how solar panels store energy for cloudy days?

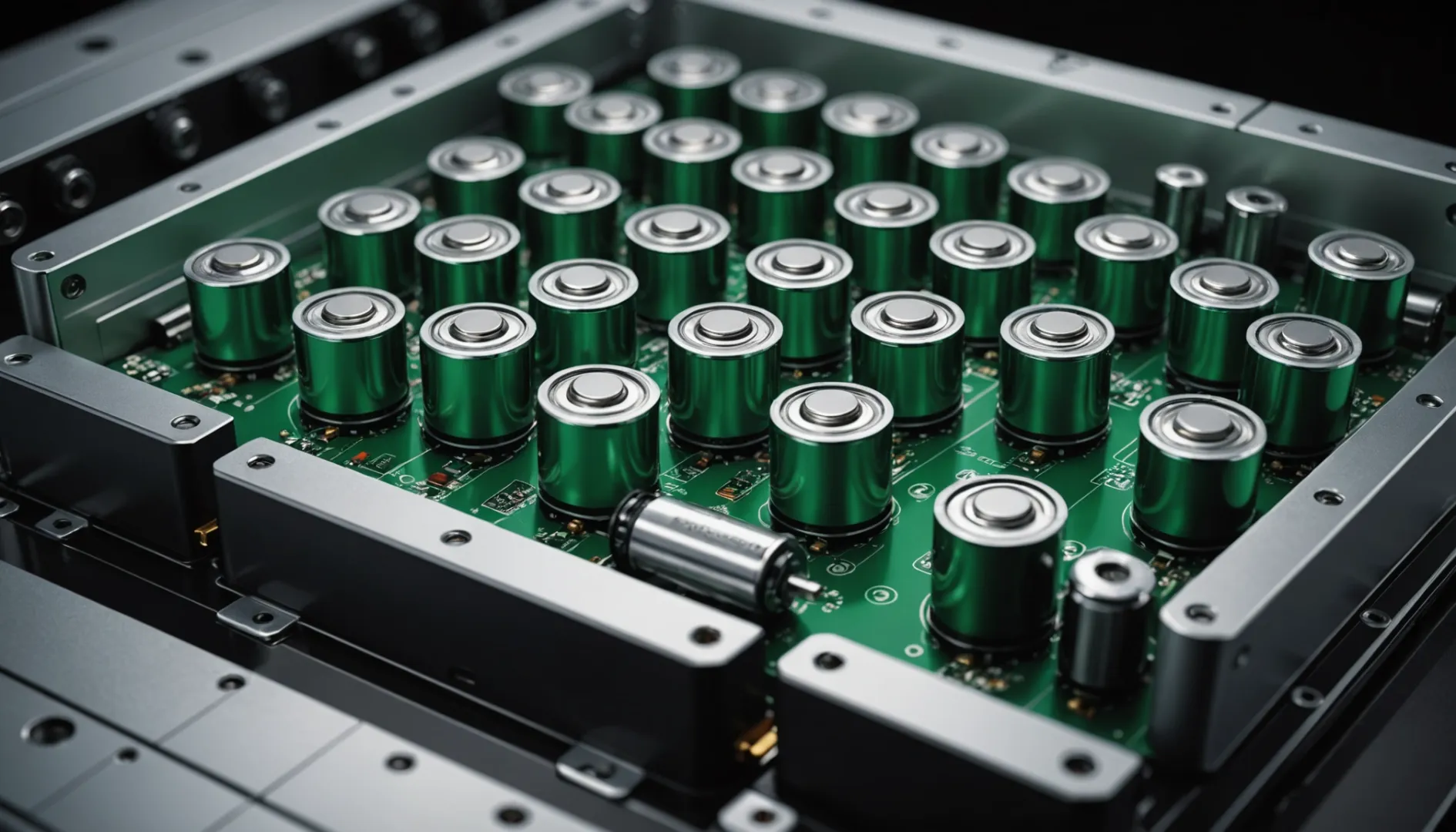

A lithium battery module is like a team of tiny powerhouses working together. It's a collection of lithium-ion cells linked to boost voltage and capacity, often found in electric cars and energy storage systems. Equipped with a Battery Management System (BMS), it ensures safety and optimal performance.

I remember when I first peeked under the hood of an electric car. The array of battery modules seemed so complex, yet it all made sense once I learned how they work. These modules aren’t just about power; they're about precision—every cell, wire, and casing has its role. They seamlessly integrate into larger systems, ensuring efficiency and reliability. It's fascinating how these modules handle thermal dynamics, almost like having a mini control room dedicated to maintaining harmony. Whether it's powering up an electric vehicle or storing energy from solar panels, their importance in modern technology is undeniable.

Lithium battery modules use only parallel connections.False

Modules use both series and parallel connections for voltage and capacity.

Battery modules enhance thermal management in systems.True

They facilitate efficient cooling, improving overall thermal management.

How Are Lithium Battery Modules Constructed?

Ever wondered what makes our gadgets tick? Dive into the fascinating world of lithium battery modules and discover their intricate construction.

Lithium battery modules are crafted by linking multiple lithium-ion cells in series or parallel, integrating a battery management system, and encasing them in sturdy housing. This ensures superior voltage, capacity, and thermal management.

The Foundation: Cell Selection and Connection

I remember the first time I opened up an old gadget, curious to see what powered it. Beneath the sleek casing lay a world of tiny cells, each a powerhouse in its own right. Constructing lithium battery modules begins just like that—with selecting these little dynamos, lithium-ion cells. It's a meticulous process, akin to choosing the perfect apples for a pie. Each cell must match in capacity, impedance, and voltage to ensure the module performs consistently. Depending on whether you want to increase voltage or boost capacity, these cells are connected in series or parallel. The connection methods—welding or compression—aren't just technical jargon; they're the glue that holds everything together. This stage sets the stage for the module's electrical prowess.

Integrating the Battery Management System (BMS)

When I learned about the Battery Management System1, it reminded me of a careful conductor overseeing an orchestra. The BMS ensures safety by preventing overcharging or discharging and balances the cells to prolong life. This involves connecting sensors and control circuits that keep a vigilant eye on each cell's status. Imagine it as a vigilant guardian, always on watch to ensure harmony within the module.

Enclosure and Thermal Management

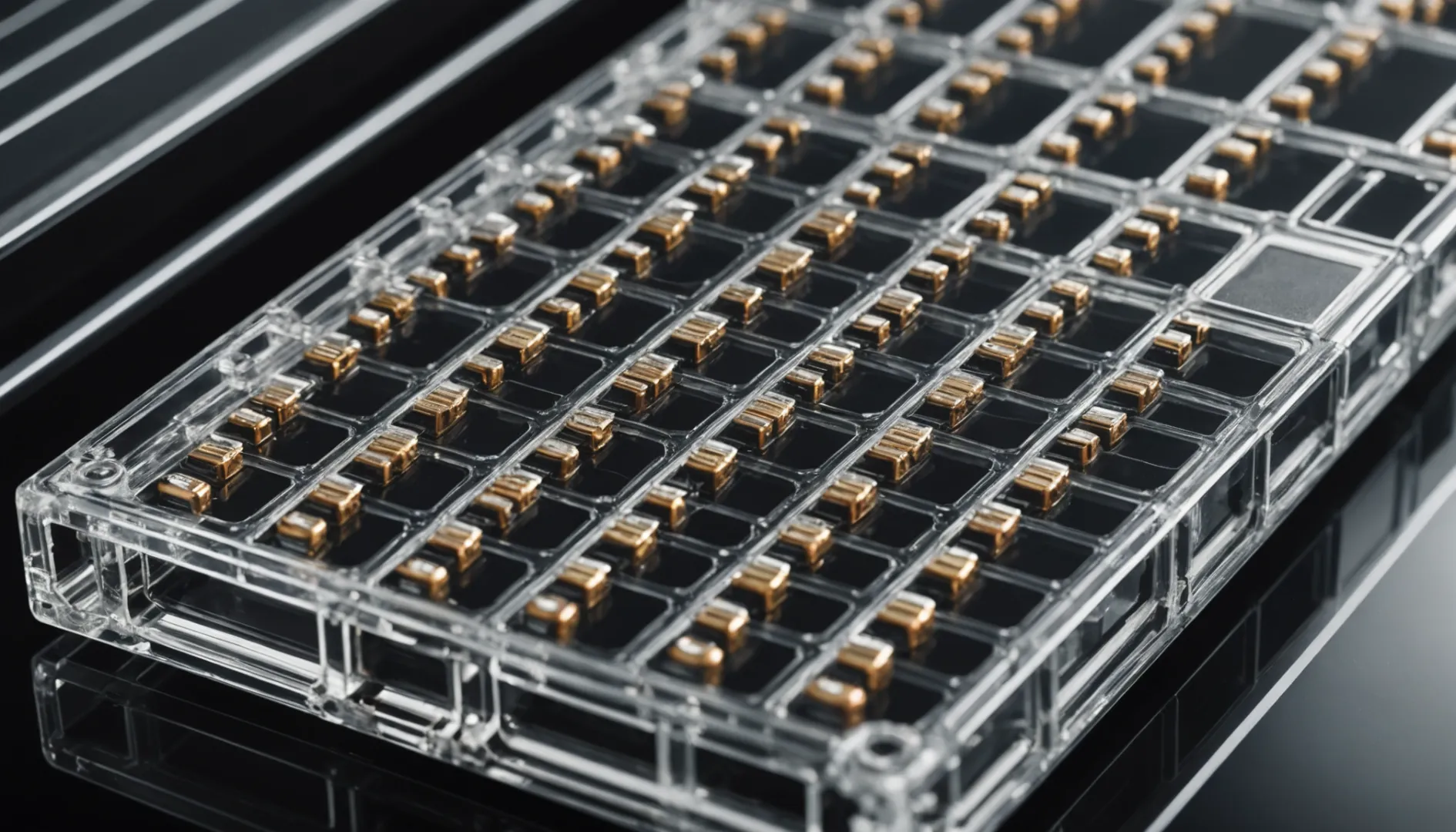

Once assembled, these cells and their trusty BMS find their home in a protective enclosure. Think of it as wrapping your precious gadgets in bubble wrap before a move. This casing isn't just about protection; it's about ensuring structural integrity against physical and environmental threats. Depending on what it's meant for, the materials can range from plastic to metal. Effective thermal management is crucial here—features like heat sinks or ventilation channels are designed to keep things cool under pressure. This aspect is vital for maintaining top-notch performance and safety no matter where your battery goes.

Customization and Standardization

Lithium battery modules offer wonderful flexibility—like customizing your favorite meal to suit your taste. They can be tailored to meet specific voltage, capacity, and form factor requirements or stick to standard configurations for broad use. This adaptability allows manufacturers to craft modules for diverse applications, whether in electric vehicles2, energy storage systems, or industrial equipment. The choice between custom and standard modules often boils down to cost, production scale, and industry-specific needs.

Lithium battery modules increase voltage beyond single cells.True

Modules combine multiple cells, boosting voltage and capacity.

Battery modules eliminate the need for a BMS.False

Modules include a BMS for monitoring and control of cells.

What Role Does a Battery Management System Play in a Module?

Ever wondered why your electric vehicle's battery doesn’t overheat or die suddenly? Let’s dive into the magic of the Battery Management System (BMS) that makes it all possible.

A Battery Management System (BMS) plays a crucial role in a module by ensuring optimal performance through monitoring and balancing cell voltage, managing temperature, and implementing safety mechanisms against overcharging or overheating. This system enhances battery lifespan and efficiency, making it essential for applications like electric vehicles and energy storage systems.

Monitoring and Balancing Cell Voltage

I remember the first time I realized how important it is to keep things balanced—kind of like juggling! The BMS does something similar by monitoring each cell's voltage in a battery module. This little hero makes sure no cell gets left behind or overworked, which would be like letting one of those juggling balls fall flat on the floor. By keeping everything in sync, the BMS prevents potential disasters, like damage from overcharging or discharging. Imagine trying to bake a cake and forgetting one ingredient; it just wouldn’t work. That’s how crucial balance is for our batteries.

Thermal Management and Safety

There was this one summer where my car felt like an oven, and I remember thinking, "I hope my battery can handle this heat!" That's where the BMS steps in with its temperature management skills. It’s like having an internal air conditioner for the battery, constantly checking to make sure things don’t get too hot and bothered. If the temperature spikes, the BMS will cool things down or sound an alarm—a bit like my phone’s weather app warning me about a heatwave! This feature is vital because overheating can lead to thermal runaway, which is as scary as it sounds. If you want to learn more about thermal management techniques3, there are tons of resources out there.

Protection Against Overcharging and Overheating

Imagine plugging in your phone overnight and waking up to find it fried! Overcharging is a real threat, but the BMS acts as a guardian angel, cutting off power when needed to prevent such disasters. Especially in electric vehicles and large storage systems, this level of protection is not just nice-to-have; it’s a must-have. You can delve into overcharging prevention4 to see how these systems keep our devices safe.

Enhancing Longevity and Efficiency

I’ve always thought about how to get the most mileage out of my gadgets before they need replacing. The BMS is like that wise friend who knows exactly when to take a break and recharge. By managing charging cycles effectively, it significantly extends the battery's lifespan and keeps everything running smoothly. Want to get nerdy about battery lifespan enhancement5? There’s a wealth of studies that’ll satisfy your curiosity.

Integration with Advanced Technologies

With technology evolving at warp speed, BMS has hopped onto the IoT bandwagon for real-time monitoring and analytics. It’s like having a fitness tracker for your battery, providing insights and predicting maintenance needs before problems arise. If you’re as fascinated by smart tech as I am, exploring how IoT impacts battery management advancements6 will open up a world of possibilities.

A BMS is essential for battery module safety.True

The BMS monitors and controls battery conditions, preventing failures.

Battery modules are only used in electric vehicles.False

Battery modules are also used in energy storage and industrial equipment.

Why Are Lithium Battery Modules Preferred in Electric Vehicles?

I remember the first time I test drove an electric vehicle and felt the thrill of its silent power. It made me curious—what fuels this incredible performance? Let’s dive into why lithium battery modules are the powerhouse behind EVs.

Lithium battery modules are the go-to choice for electric vehicles because they pack high energy density, excellent thermal management, and modular design into a compact package, boosting EV performance and efficiency.

Enhanced Energy Density

When I think about road trips in my electric car, it’s all about that thrilling moment of freedom on the open road, not worrying about constant recharging stops. That’s thanks to the high energy density of lithium battery modules. These batteries can store a lot of energy without weighing down the vehicle, allowing for longer journeys on a single charge. It’s like having a trusty backpack that fits everything you need without breaking your back. Compared to older technologies like nickel-metal hydride or lead-acid, lithium batteries strike the perfect balance between weight and power, making them ideal for EVs7.

Efficient Thermal Management

I’ve always been amazed at how cool my car remains even after a long drive on a hot day. This is where lithium battery modules shine with their efficient thermal management systems. These systems are like having an internal A/C unit for the battery, keeping it from overheating and ensuring it lasts longer. Integrated cooling systems and smart cell arrangements work together to maintain the right temperature, preventing any hiccups on those scorching summer drives. You can learn more about how thermal management works8 in modern EVs.

Modularity and Ease of Maintenance

Imagine if fixing your car battery was as simple as swapping out a Lego piece! That’s pretty much what the modularity of lithium battery modules offers. Each module can be individually tested and replaced without tearing apart the entire system. This saves time and reduces maintenance headaches. Plus, as tech evolves, you can easily upgrade parts without having to buy a whole new battery pack, keeping your EV ready for any future advancements. This approach ensures that EVs stay competitive9 in the market.

Consistency and Safety Features

What gives me peace of mind is knowing there’s a little guardian inside each lithium battery module—the Battery Management System (BMS). It’s like having a vigilant friend watching over the cells, balancing their voltage, tracking how often they charge, and shielding them from overcharging. These systems ensure that every part of the battery works harmoniously, maintaining safety and efficiency. With their robust build, lithium modules also stand strong against physical damage or overheating mishaps. The importance of BMS10 cannot be overstated when it comes to keeping our rides safe.

Environmental and Economic Benefits

Switching to an electric vehicle felt like doing my bit for Mother Earth, knowing it’s powered by lithium batteries that support zero-emission journeys. They’re recyclable and produce fewer lifecycle emissions than traditional engines, which is a win-win for both the environment and our future. Economically, as production ramps up, the cost of these batteries per kilowatt-hour is dropping, making EVs more budget-friendly for everyone. Explore how cost reductions impact11 the EV industry.

Lithium modules improve EV battery lifespan.True

Lithium battery modules enhance lifespan by efficient thermal management.

Battery modules are only used in electric vehicles.False

Modules are also used in energy storage and industrial equipment.

What Challenges Are Involved in Manufacturing Lithium Battery Modules?

Have you ever wondered what it really takes to make lithium battery modules? It's like a high-stakes puzzle of engineering and logistics!

Manufacturing lithium battery modules involves challenges such as ensuring cell consistency, managing heat, and maintaining rigorous quality control throughout the production process.

Ensuring Cell Consistency

I remember the first time I peered into the world of lithium battery modules. It felt like trying to bake a perfect cake every single time. Each cell in a module must match its companions in capacity, impedance, and voltage. Think of it like making sure each cupcake rises just right—one slip-up, and the whole batch can be off. This demands careful testing and selection of cells, which is as tedious as sifting through hundreds of recipes to find that one perfect match. The advanced equipment used for sorting cells adds layers of complexity and cost, but it’s a necessary step to avoid any performance hiccups or shortened lifespans.

Managing Heat Effectively

Heat management is another beast altogether. Imagine running a marathon while wearing a thick winter coat—that's how these cells feel when they generate heat during charge and discharge cycles. Effective cooling strategies are crucial to prevent damage and ensure safety, akin to providing ice packs and water breaks during a long run. But incorporating cooling systems can make the modules heavier and bulkier, posing a real design conundrum.

Quality Control in Production

I once spoke with a friend who works in battery manufacturing, and their tales of quality control reminded me of an intense game of Jenga—one wrong move could topple the entire structure. Every component, from tiny cells to intricate connectors, must meet stringent specifications to guarantee reliability. Implementing comprehensive quality assurance12 processes can be time-consuming and costly, much like assembling a complex puzzle without the picture on the box. Automation and advanced monitoring technologies are often employed to streamline efficiency, but they require significant investment and know-how.

Integrating Battery Management Systems (BMS)

Integrating a reliable battery management system (BMS) is like adding a smart thermostat to your home—it monitors everything to ensure smooth operation. The BMS balances cells and prevents overcharging or overheating, requiring sophisticated algorithms and real-time data processing. It's no small feat designing such a system; it demands precision and technical prowess.

Supply Chain and Material Sourcing

Navigating the supply chain for these modules feels like playing chess on a global scale. Sourcing high-quality materials like lithium, cobalt, and nickel is challenging due to market fluctuations and geopolitical factors. I’ve heard stories from colleagues about how this juggling act impacts production costs and sustainability efforts. Keeping these factors in balance while ensuring ethical sourcing practices is a continual challenge.

Regulatory Compliance and Safety Standards

Finally, there’s the maze of regulatory compliance. Manufacturers must adhere to safety standards and regulations specific to different regions—a bit like tailoring suits for individuals with vastly different measurements. These regulations are vital for ensuring safety and reliability but require staying on top of evolving guidelines, much like keeping pace with fashion trends in an ever-changing industry.

Battery modules increase voltage beyond single cells.True

Modules combine cells to boost voltage and capacity.

Lithium battery modules don't require a BMS.False

A BMS is crucial for monitoring and control in modules.

Conclusion

A lithium battery module comprises interconnected lithium-ion cells, enhancing voltage and capacity while integrating a Battery Management System for safety and efficiency in applications like electric vehicles and energy storage.

-

Learn about BMS role in safety and performance enhancement. ↩

-

Discover how these modules power electric vehicles efficiently. ↩

-

Learn about various methods to prevent thermal runaway. ↩

-

Discover how BMS prevents overcharging hazards. ↩

-

Explore effective strategies for prolonging battery life. ↩

-

Understand IoT's role in modern battery management. ↩

-

Explore why lithium batteries outperform other types for EVs. ↩

-

Understand the role of thermal management in battery longevity. ↩

-

Learn how modularity enhances maintenance and upgrades. ↩

-

Discover how BMS ensures safety and efficiency in batteries. ↩

-

See how decreasing costs make EVs more affordable. ↩

-

Discover strategies for maintaining high standards in battery production.

TOWO Power Is a leader for solar product solution company from China ↩